How To Preheat Steel For Welding . Preheating is the process of heating the workpiece to be welded to a temperature higher than the ambient temperature, either before or during welding. When do you need to preheat before welding? Joints with high restraint force can reduce shrinkage stress after. What do you need to consider to make the right choice? Preheating involves heating the area around the weld joint or the entire part to a specified temperature before welding. Which preheating method is correct for your application? This reduces the cooling rate of the weld and drives out. Preheating is used primarily to reduce the cooling rate of the weld, heat affected zone and adjacent base metal. This reduces susceptibility to cold (hydrogen induced) cracking. Preheating is a process to slow down the rapid heating and cooling process in the welding area. Metal type, thickness, current metal temperature, ambient temperature, and welding process determine the required preheat.

from weldingpros.net

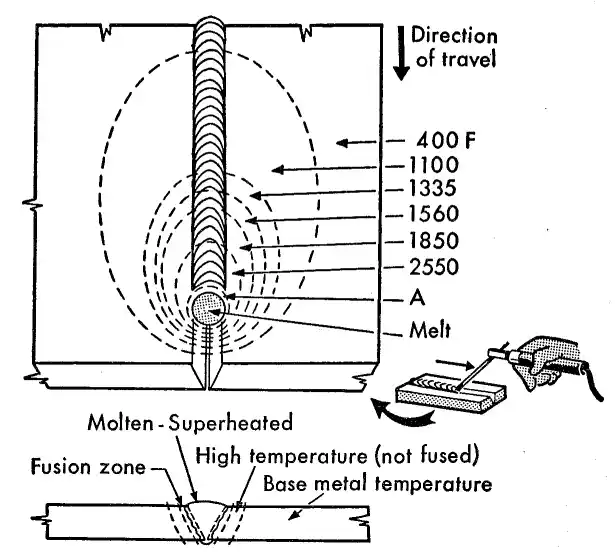

Preheating is the process of heating the workpiece to be welded to a temperature higher than the ambient temperature, either before or during welding. Preheating involves heating the area around the weld joint or the entire part to a specified temperature before welding. When do you need to preheat before welding? Preheating is a process to slow down the rapid heating and cooling process in the welding area. Which preheating method is correct for your application? What do you need to consider to make the right choice? Preheating is used primarily to reduce the cooling rate of the weld, heat affected zone and adjacent base metal. Joints with high restraint force can reduce shrinkage stress after. This reduces susceptibility to cold (hydrogen induced) cracking. This reduces the cooling rate of the weld and drives out.

Preheating In Welding Steel, Stainless, And Aluminum

How To Preheat Steel For Welding Preheating involves heating the area around the weld joint or the entire part to a specified temperature before welding. Which preheating method is correct for your application? Preheating is the process of heating the workpiece to be welded to a temperature higher than the ambient temperature, either before or during welding. This reduces the cooling rate of the weld and drives out. Preheating is a process to slow down the rapid heating and cooling process in the welding area. Preheating involves heating the area around the weld joint or the entire part to a specified temperature before welding. Preheating is used primarily to reduce the cooling rate of the weld, heat affected zone and adjacent base metal. What do you need to consider to make the right choice? When do you need to preheat before welding? Metal type, thickness, current metal temperature, ambient temperature, and welding process determine the required preheat. Joints with high restraint force can reduce shrinkage stress after. This reduces susceptibility to cold (hydrogen induced) cracking.

From technoweld.com.au

The basics of preheat Technoweld How To Preheat Steel For Welding Preheating is a process to slow down the rapid heating and cooling process in the welding area. This reduces susceptibility to cold (hydrogen induced) cracking. What do you need to consider to make the right choice? Metal type, thickness, current metal temperature, ambient temperature, and welding process determine the required preheat. When do you need to preheat before welding? Preheating. How To Preheat Steel For Welding.

From www.youtube.com

Induction Heating Cuts Preheat Time, Provides Uniform Heating for How To Preheat Steel For Welding What do you need to consider to make the right choice? Which preheating method is correct for your application? Preheating is the process of heating the workpiece to be welded to a temperature higher than the ambient temperature, either before or during welding. When do you need to preheat before welding? Joints with high restraint force can reduce shrinkage stress. How To Preheat Steel For Welding.

From www.youtube.com

Preheating Metal to 700 degrees Preparation before Welding YouTube How To Preheat Steel For Welding Metal type, thickness, current metal temperature, ambient temperature, and welding process determine the required preheat. What do you need to consider to make the right choice? When do you need to preheat before welding? Preheating is a process to slow down the rapid heating and cooling process in the welding area. Preheating is the process of heating the workpiece to. How To Preheat Steel For Welding.

From www.youtube.com

Preheat before welding YouTube How To Preheat Steel For Welding This reduces susceptibility to cold (hydrogen induced) cracking. Preheating is the process of heating the workpiece to be welded to a temperature higher than the ambient temperature, either before or during welding. Preheating is used primarily to reduce the cooling rate of the weld, heat affected zone and adjacent base metal. When do you need to preheat before welding? Joints. How To Preheat Steel For Welding.

From www.canadianmetalworking.com

Welding preheat options reconsidered How To Preheat Steel For Welding Joints with high restraint force can reduce shrinkage stress after. Which preheating method is correct for your application? This reduces the cooling rate of the weld and drives out. This reduces susceptibility to cold (hydrogen induced) cracking. When do you need to preheat before welding? Metal type, thickness, current metal temperature, ambient temperature, and welding process determine the required preheat.. How To Preheat Steel For Welding.

From www.comaintel.com

Metal Preheating « Comaintel How To Preheat Steel For Welding Joints with high restraint force can reduce shrinkage stress after. This reduces the cooling rate of the weld and drives out. Preheating is a process to slow down the rapid heating and cooling process in the welding area. Metal type, thickness, current metal temperature, ambient temperature, and welding process determine the required preheat. When do you need to preheat before. How To Preheat Steel For Welding.

From www.westermans.com

What You Need to Know About PreHeating Before Welding. How To Preheat Steel For Welding This reduces susceptibility to cold (hydrogen induced) cracking. Preheating is a process to slow down the rapid heating and cooling process in the welding area. Metal type, thickness, current metal temperature, ambient temperature, and welding process determine the required preheat. Preheating is used primarily to reduce the cooling rate of the weld, heat affected zone and adjacent base metal. When. How To Preheat Steel For Welding.

From www.mig-welding.co.uk

Welding Hardox Steels How To Preheat Steel For Welding Metal type, thickness, current metal temperature, ambient temperature, and welding process determine the required preheat. Preheating is used primarily to reduce the cooling rate of the weld, heat affected zone and adjacent base metal. Which preheating method is correct for your application? Preheating is the process of heating the workpiece to be welded to a temperature higher than the ambient. How To Preheat Steel For Welding.

From qaqctips.blogspot.com

Weld Joint Preheating Requirements and advantages QA/QC Tips & Guides How To Preheat Steel For Welding This reduces susceptibility to cold (hydrogen induced) cracking. Joints with high restraint force can reduce shrinkage stress after. Preheating is a process to slow down the rapid heating and cooling process in the welding area. Preheating involves heating the area around the weld joint or the entire part to a specified temperature before welding. Preheating is used primarily to reduce. How To Preheat Steel For Welding.

From qaqctips.blogspot.com

Weld Joint Preheating Requirements and advantages QA/QC Tips & Guides How To Preheat Steel For Welding Which preheating method is correct for your application? When do you need to preheat before welding? Preheating is a process to slow down the rapid heating and cooling process in the welding area. This reduces susceptibility to cold (hydrogen induced) cracking. Joints with high restraint force can reduce shrinkage stress after. This reduces the cooling rate of the weld and. How To Preheat Steel For Welding.

From www.youtube.com

WHY PREHEATING IS REQUIRED IN WELDING YouTube How To Preheat Steel For Welding Joints with high restraint force can reduce shrinkage stress after. Preheating is used primarily to reduce the cooling rate of the weld, heat affected zone and adjacent base metal. Preheating involves heating the area around the weld joint or the entire part to a specified temperature before welding. Preheating is the process of heating the workpiece to be welded to. How To Preheat Steel For Welding.

From www.scribd.com

Welding Preheat Chart How To Preheat Steel For Welding Preheating is a process to slow down the rapid heating and cooling process in the welding area. Preheating is the process of heating the workpiece to be welded to a temperature higher than the ambient temperature, either before or during welding. Joints with high restraint force can reduce shrinkage stress after. Metal type, thickness, current metal temperature, ambient temperature, and. How To Preheat Steel For Welding.

From waterwelders.com

Warming Up to Welding The Whys and Hows of Preheating WaterWelders How To Preheat Steel For Welding This reduces the cooling rate of the weld and drives out. Preheating involves heating the area around the weld joint or the entire part to a specified temperature before welding. This reduces susceptibility to cold (hydrogen induced) cracking. Preheating is a process to slow down the rapid heating and cooling process in the welding area. Preheating is used primarily to. How To Preheat Steel For Welding.

From www.damatech.com

Hardox Welding Damatech How To Preheat Steel For Welding What do you need to consider to make the right choice? Metal type, thickness, current metal temperature, ambient temperature, and welding process determine the required preheat. This reduces susceptibility to cold (hydrogen induced) cracking. Preheating is the process of heating the workpiece to be welded to a temperature higher than the ambient temperature, either before or during welding. Preheating involves. How To Preheat Steel For Welding.

From weldinganswers.com

Preheat and Interpass Temperature for Structural Steels WELDING ANSWERS How To Preheat Steel For Welding Preheating is a process to slow down the rapid heating and cooling process in the welding area. Which preheating method is correct for your application? Preheating is the process of heating the workpiece to be welded to a temperature higher than the ambient temperature, either before or during welding. Preheating is used primarily to reduce the cooling rate of the. How To Preheat Steel For Welding.

From www.onestopndt.com

Why Preheating on steels? its benefits and requirements How To Preheat Steel For Welding This reduces susceptibility to cold (hydrogen induced) cracking. Preheating is the process of heating the workpiece to be welded to a temperature higher than the ambient temperature, either before or during welding. Preheating involves heating the area around the weld joint or the entire part to a specified temperature before welding. Preheating is a process to slow down the rapid. How To Preheat Steel For Welding.

From www.twi-global.com

Why is preheat used when arc welding steel, and how is it applied? TWI How To Preheat Steel For Welding Metal type, thickness, current metal temperature, ambient temperature, and welding process determine the required preheat. Which preheating method is correct for your application? Preheating is a process to slow down the rapid heating and cooling process in the welding area. Joints with high restraint force can reduce shrinkage stress after. This reduces susceptibility to cold (hydrogen induced) cracking. When do. How To Preheat Steel For Welding.

From thegraduateengineer.com

What is Weld Preheating, Its Importance and When To Use It How To Preheat Steel For Welding Preheating involves heating the area around the weld joint or the entire part to a specified temperature before welding. Which preheating method is correct for your application? This reduces susceptibility to cold (hydrogen induced) cracking. Joints with high restraint force can reduce shrinkage stress after. This reduces the cooling rate of the weld and drives out. Preheating is a process. How To Preheat Steel For Welding.